KBT450 Series – Compact & Flexible Freshness Solution. Advanced Freshness Technology for Small to Medium Production

Preserve Freshness. Improve Shelf Life. Optimize Small-Batch Production.

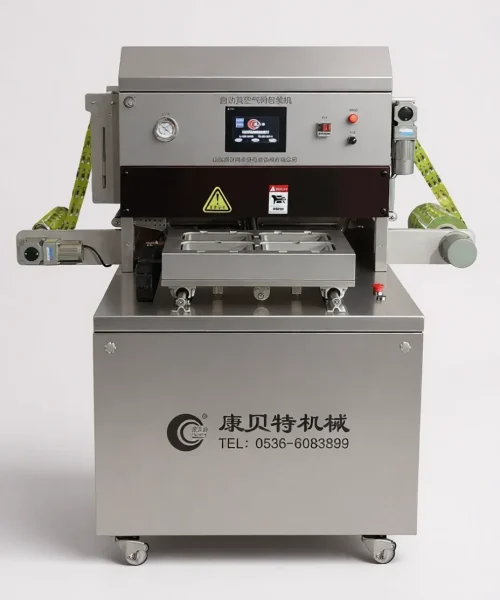

The KBT450 Series Vertical Modified Atmosphere Packaging Machine is a compact, vertical-type MAP solution designed for small to medium production capacities. It packages food products in pre-made plastic trays, bowls, or cups of various shapes (rectangular, square, round, triangular, etc.), making it ideal for fresh food retail, R&D labs, and specialty food producers.

By replacing the air inside the package with a controlled gas mixture, the KBT450 series can extend shelf life by 50%–500%, without artificial preservatives, while maintaining natural appearance and taste.

Core Advantages:

Clean Label Preservation: Extends shelf life naturally, reducing the need for chemical additives.

Gentle Packaging: Unlike vacuum-only packing, MAP protects the shape and texture of soft or delicate foods.

Compact Vertical Design: Small footprint, ideal for limited workshop or retail backroom space.

Flexible Output Options: Available with single or dual molds to match different productivity needs.

The KBT450 Series uses a reliable Vacuum – Gas Filling – Sealing process:

Vacuum: Air is evacuated from the tray to remove oxygen and contaminants.

Gas Filling: A precise mixture of food-grade gases (N₂, CO₂, O₂, or others) is injected.

Sealing: The tray is hermetically sealed with top film to lock in the modified atmosphere.

Compared with traditional gas flushing, this method ensures higher gas purity and lower gas consumption, resulting in more stable shelf-life performance.

Custom Mold Design: Each machine is tailored to the customer’s tray size and product requirements.

High Hygiene Standards: Constructed from food-grade SUS304 stainless steel, fully compliant with food safety regulations.

Precise Control System: Mitsubishi PLC + touch screen interface for easy parameter setting and stable operation.

Consistent Sealing Quality: Advanced temperature control and precision servo positioning ensure uniform seals.

Scalable Performance: Choose between single-mold or dual-mold configurations for higher efficiency.

Designed for industries requiring extended shelf life, moisture protection, and professional presentation.

A. Food Industry

Meat & Poultry: Fresh m

KANGBEITE offers two versions of the KBT450 Vertical MAP Machine:

KBT450/1S – Single mold configuration

Ideal for lower output or frequent product changes

KBT450/2S – Dual mold configuration (alternating operation)

Higher efficiency and increased hourly output

The KBT450 Series is widely used for fresh and semi-fresh food packaging:

Fresh beef, pork, lamb, chicken

Maintains color, freshness, and extended shelf life

Fresh fish fillets, shrimp, shellfish

Prevents package collapse and protects delicate textures

Cooked meals, deli products, convenience foods

Pastries, cakes, desserts, nuts, and snack products

KBT450 Series Vertical MAP Packaging Machine – Reference Specifications

| Model | KBT450/1S | KBT450/2S |

|---|---|---|

| Tray Size | No limitation | No limitation |

| Trays per Cycle | 2 / 4 / 6 pcs | 2 / 4 / 6 pcs |

| Vacuum Pump | BUSCH 100 m³/h | BUSCH 100 m³/h |

| Power Supply | Customized, 3 Phase | Customized, 3 Phase |

| Total Power | 7.5 kW | 7.5 kW |

| Machine Dimensions (mm) | 1500 × 1500 × 1800 | 1500 × 1900 × 1800 |

| Machine Weight | 450 kg | 600 kg |

| Packing Speed (4 trays/cycle) | 400–600 trays/hour | 700–800 trays/hour |

| Max Film Roll Diameter | 260 mm | 260 mm |

| Compressed Air | 0.6–0.8 MPa | 0.6–0.8 MPa |

| Gas Type | N₂ / CO₂ / O₂ / Mixed Gas | N₂ / CO₂ / O₂ / Mixed Gas |

| Gas Mixer | Optional | Optional |

Note: Each KBT450 machine is customized according to product and tray specifications. The above data is for reference only.

Pre-made Plastic Trays: PP, PET, CPET (custom shapes and sizes)

Top Sealing Films: High-barrier films, anti-fog options available

Gas Cylinders: Food-grade O₂, N₂, CO₂ (purity ≥ 99.99%)

Gas Pressure Regulators

Gas Mixer: Required when mixed gas recipes are needed

Nitrogen Generator: Optional for on-site nitrogen supply

Air Compressor Set:

Air compressor (7.5 kW)

Air storage tank (1 m³)

Air dryer and air filter

Q1: Is the KBT450 suitable for supermarkets or small factories?

Yes. The compact vertical design and semi-automatic operation make it ideal for supermarkets, R&D labs, and small to medium food producers.

Q2: Can one machine handle different tray sizes?

Yes, but different tray sizes require different molds. Molds are custom-designed based on your packaging needs.

Q3: What gases can be used with the KBT450?

The machine supports pure or mixed gases, including N₂, CO₂, O₂, and other food-grade gases.

Q4: What is the advantage of dual-mold (2S) configuration?

The dual molds work alternately, significantly increasing output and reducing idle time.

Q5: What do I need to prepare before installation?

3-phase industrial power supply

Compressed air (0.6–0.8 MPa)

Food-grade gas supply (cylinders or nitrogen generator)

Control System: Mitsubishi PLC + Mitsubishi touch screen

Drive System: High-precision Mitsubishi servo motor

Temperature Control: Mitsubishi 4-channel temperature control module

Safety Features: Emergency stop, alarm system, open-phase and anti-phase protection

Molds: Aluminum-magnesium alloy molds, high strength, corrosion-resistant, long service life

Optional Features: Date printing via inkjet system

Email:kbt@kbtfoodpack.com

Tel:+86 15006621717

Add:No. 9999, Mizhou East Road, Zhucheng City, Weifang City, Shandong Province

© 2026 Created with KBT

WhatsApp us