otary Operation, Automatic Unloading, Dedicated Production.

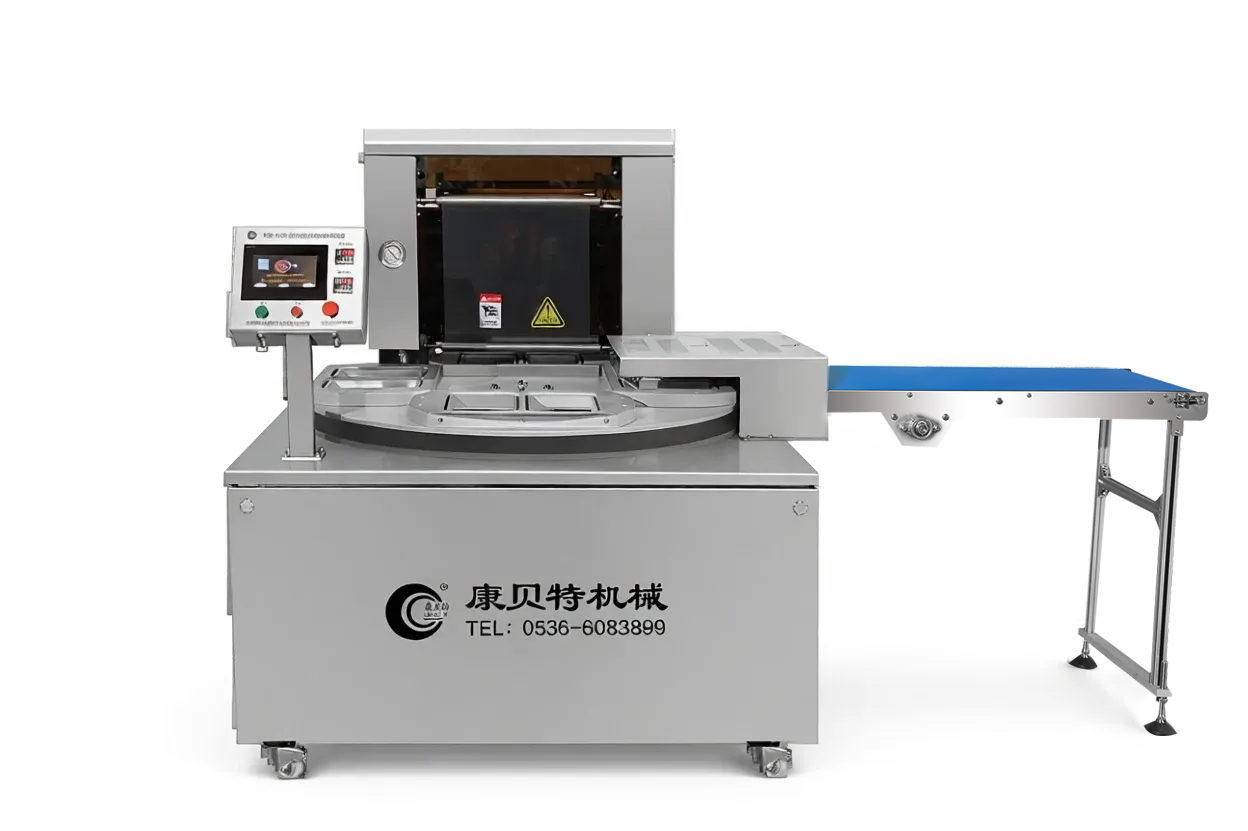

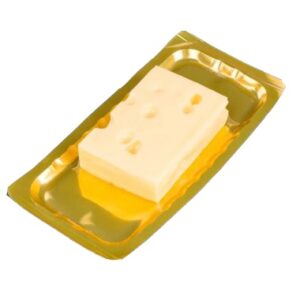

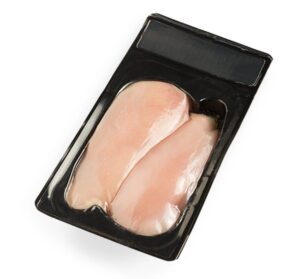

The VSP1200 Series is KBT’s specialized rotary solution designed for food processors requiring medium to large production capacities. Unlike vertical models, this machine utilizes a rotating mold system that streamlines the workflow, allowing for simultaneous loading and sealing actions. It is engineered for stability and speed, delivering perfectly preserved products with the signature “second skin” look.

How It Works:

The VSP1200 operates on a rotary turntable mechanism. The operator places pre-made trays into the open mold cavities. The table rotates the trays into the vacuum chamber where the skin film is heated, draped, and sealed. Once the cycle is complete, the mold rotates out, and the unique automatic unloading system lifts and transfers the finished packs onto a conveyor belt.

Why Choose the VSP1200?

The VSP1200 is the preferred choice for businesses with established product lines requiring consistent, high-speed output.

| Item | Specification |

| Model No. | VSP-1200 |

| Maximum Packing Tray Size | Customizable |

| Maximum Rolled Film Width | Customizable |

| Maximum Rolled Film Diameter | 280 mm |

| Packing Speed | 300–400 trays/hour |

| Power Supply | 380 V / 50 Hz |

| Air Pressure | 0.6–0.8 MPa |

| Total Power | 9 kW |

| Vacuum Pump Flow Rate | 200 m³/h |

| Vacuum Pump Motor Power | 5.5 kW |

| Vacuum Pump Brand | BUSCH |

| Machine Weight | 700 kg |

| Overall Dimensions (mm) | 1800 × 1400 × 1650 |

Q1: Can I change molds on the VSP1200 to run different tray sizes?

No. The VSP1200 is designed for high-efficiency, single-format production. It cannot change molds; one machine is dedicated to one tray size. If you require multi-tray flexibility, please consider our VSP450A or other models.

Q2: What is the advantage of the Rotary system?

The rotary system allows for a smoother workflow. While one side is sealing, the other side is exposed for loading. Combined with the automatic unloading belt, it creates a seamless production rhythm that is faster than standard vertical machines.

Q3: What vacuum pump is used?

We use industry-leading BUSCH or Rietschle vacuum pumps (200 m³/h). These are high-capacity pumps designed to remove air rapidly, essential for maintaining the high speed (500-800 trays/hr) of this machine.

Q4: What information is needed for a quote?

Because the mold is fixed and customized:

Email:kbt@kbtfoodpack.com

Tel:+86 15006621717

Add:No. 9999, Mizhou East Road, Zhucheng City, Weifang City, Shandong Province

© 2026 Created with KBT

WhatsApp us