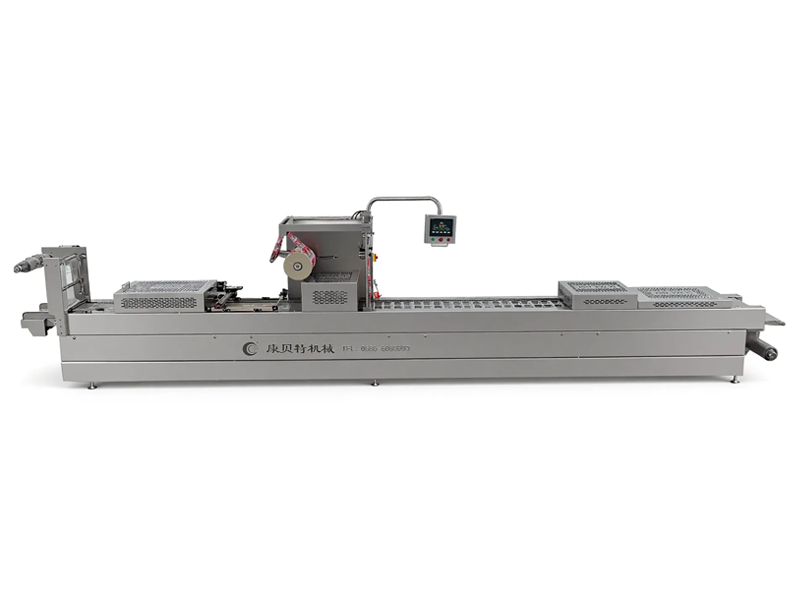

High-Speed, Continuous Form-Fill-Seal Solution for Industrial Production

One Machine, Infinite Possibilities.

The DRZ Series Thermoforming Vacuum Packaging Machine utilizes rollstock technology to automatically form containers, fill products (manually or automatically), vacuum seal, and cut—all in one continuous process.

Maximum Efficiency: Operates at 5–10 cycles per minute. A single machine can replace 5–8 manual workers, significantly reducing labor costs and increasing throughput.

Heavy-Duty Construction: Built with a Magnesium-Aluminum Alloy frame for superior rigidity and wrapped in SUS304 Food-Grade Stainless Steel. It is corrosion-resistant, hygienic, and designed for wash-down environments.

Top-Tier Components: Equipped with original Busch Vacuum Pumps (Germany) and a Mitsubishi PLC (Japan) control system, ensuring stable performance and a design life of over 10 years.

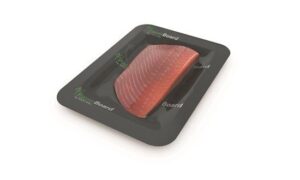

High Flexibility: Compatible with both Flexible Films and Rigid Trays. Molds are fully customizable to fit specific product shapes, from steaks and fish fillets to industrial hardware.

How It Works:

This machine, also known as a Rollstock Wrapper, uses two rolls of film. The Bottom Film is heated and formed into containers (trays/pockets). After loading the product, the Top Film seals the package under a high vacuum environment. Finally, the cross-cutting and longitudinal cutting systems discharge the finished individual packs.

Why Choose Our Thermoformer?

Cost Savings: Rollstock film is significantly cheaper than pre-made pouches (saving 20–40% on material costs) and requires less storage space.

Customized Tooling: Every mold is custom-engineered based on your product’s exact dimensions (L x W x H). Whether packing whole chickens or small electronic parts, the package fits perfectly.

The Smart Alternative: We offer a cost-effective alternative to expensive brands like Multivac. You get the same build quality (Alloy frame + branded components) at a much faster ROI (Return on Investment).

User-Friendly Control: The PLC system with a touchscreen interface allows for recipe storage, one-key format changeovers, and automatic fault diagnostics.

Designed for industries requiring extended shelf life, moisture protection, and professional presentation.

A. Food Industry

Meat & Poultry: Fresh meat cuts, frozen meat blocks, sausages, bacon, ham, ground beef, meatballs, burger patties, whole chickens, and duck breasts.

Seafood & Fish: Fish fillets, whole fish, shrimp, lobster tails, squid rings, and smoked fish (prevents freezer burn and oxidation).

Dairy & Eggs: Cheese blocks, cheese slices, butter, quail eggs, salted eggs, and boiled eggs.

Produce & Others: Durian pulp, sweet corn cobs, pickles, bean products, dried fruits, and pet food (wet/dry).

B. Non-Food & Industrial

Industrial Hardware: Tools, bearings, precision metal parts (rust and dust protection).

Electronics: Circuit boards, sensitive electronic components (moisture and oxidation protection).

Consumer Goods: Toothbrush heads, stationeries, and chemical products.

Below are the standard specifications. Note that machine length, pump size, and mold design are fully customizable based on your factory layout and output requirements.

| Name | Unit | DRZ-320 | DRZ-420 | DRZ-520 |

|---|---|---|---|---|

| Sealing Film width | mm | 293 | 393 | 495 |

| Forming Film width | mm | 322 | 422 | 520 |

| Vacuum degree | mBar | 0.1 | 0.1 | 0.1 |

| Power supply | V, Hz | 380v/50hz,3phase | 380v/50hz,3phase | 380v/50hz,3phase |

| Vacuum capacity | m3/h | 100-300 | 100-300 | 100-300 |

| Power | KW | 15 | 16 | 18 |

| Compressed air | Mpa | ≥0.6 | ≥0.6 | ≥0.6 |

| Overall dimension | mm | 5100*900*1800 | 5300*950*1860 | 6600*1080*1760 |

| Weight | KG | 1300 | 1600 | 1800 |

Power Supply: 380V / 415V / 480V (3-Phase) – Customized to local standards.

Compressed Air: >0.6 Mpa, Flow >1 m³/min.

Cooling Water: Pressure >0.15 Mpa.

Vacuum Level: <0.1 mbar.

The machine requires two rolls of film working in sync.

Bottom Film (Forming Film):

Material: Multi-layer co-extruded films (e.g., PA/PE, PA/EVOH/PE, PP/PE).

Types: Available in Flexible (soft bags) or Rigid (hard trays).

Thickness: Typically 100μm – 280μm.

Top Film (Sealing Film):

Material: Composite soft films (e.g., PA/PE, BOPET/PE) or Aluminum Foil.

Thickness: Typically 70μm – 100μm.

Feature: Can be printed with branding/logos.

Q1: What information do I need to provide for a quote?

To provide an accurate proposal, we need:

Product Details: What are you packing?

Dimensions: Length x Width x Height (mm) of the product.

Output Requirement: How many packs per hour/day?

Samples: Sending physical samples allows us to design the most efficient mold layout.

Q2: What is the lead time?

Since thermoforming machines are highly customized (especially the tooling), the standard production time is 30–60 days. This includes manufacturing, assembly, and rigorous testing before shipment.

Q3: What are the installation requirements?

Electricity: Industrial 3-phase power with a ground wire.

Compressed Air: Stable pressure >0.6 Mpa. If the compressor is far away, an air storage tank and air dryer/filter are recommended.

Environment: Flat concrete floor; temperature between -10℃ and 60℃.

Q4: How do I maintain the machine?

Vacuum Pump: Change the pump oil every 1500–2000 running hours. If the oil looks milky or black, change it immediately.

Cleaning: Keep the heating plates, silicone strips, and sealing gaskets clean.

Lubrication: Grease moving parts (bearings, connecting rods) every 30 days.

Q5: Troubleshooting Common Issues?

Low Vacuum: Check pump oil level/quality, inspect silicone gaskets for damage, and check for air leaks in the pneumatic system.

Weak Seal: Check heating temperature settings, inspect the airbag/bladder for damage, or check the booster valve.

Machine Won’t Start: Check the emergency stop button, ensure correct power phase sequence (motor not reversing), and verify air pressure.

Q6: Why choose us over Multivac?

While Multivac is the industry leader, their machines come with a premium price tag and long delivery times. We offer equivalent build quality (using the same Busch pumps and Mitsubishi electronics) and robust Magnesium Alloy frames, but at a price point that makes sense for your business, ensuring a faster ROI without compromising on performance.

Email:kbt@kbtfoodpack.com

Tel:+86 15006621717

Add:No. 9999, Mizhou East Road, Zhucheng City, Weifang City, Shandong Province

© 2026 Created with KBT

WhatsApp us