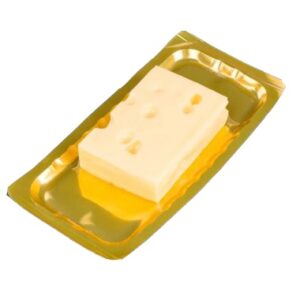

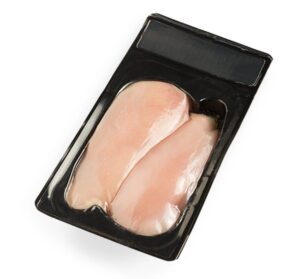

3D Presentation, Maximum Shelf Life, Zero Preservatives.

KANGBEITE’s Vacuum Skin Packaging (VSP) machines revolutionize food packaging by creating a “second skin” around your product. This technology heats a specialized top film and uses vacuum pressure to drape it tightly over the product and seal it to the entire surface of the tray. The result is a package that is visually stunning, vertically displayable, and perfectly preserved.

How It Works:

The VSP process utilizes heat and vacuum to soften the top “skin film.” The machine then pulls this film tight against the product (whether low profile or high protrusion) and seals it directly to the rigid tray or paperboard backing. All atmosphere is removed, locking the product firmly in place.

Why Choose KANGBEITE VSP Machines?

VSP is the preferred choice for high-value, premium products requiring professional presentation.

A. Fresh Protein

B. Convenience Foods

C. Other Premium Goods

| Specification Item | Details / Value |

|---|---|

| Model No. | VSP-1000 |

| Maximum Packing Tray Size | Customizable (4 trays simultaneously) |

| Maximum Rolled Film Width | Customizable |

| Maximum Rolled Film Diameter | 280 mm |

| Modified Atmosphere Packaging Speed | 300 – 1200 boxes/hour (2–8 trays per cycle) |

| Power Supply | 380 V / 50 Hz, or customizable |

| Air Pressure | 0.6 – 0.8 MPa |

| Total Power | 9 kW |

| Vacuum Pump Motor Power | 2.2 kW |

| Vacuum Pump | Busch R5-100 |

| Machine Weight | 1200 kg |

Bottom Film (Forming Film):

Material: Multi-layer co-extruded films (e.g., PA/PE, PA/EVOH/PE, PP/PE).

Types: Available in Flexible (soft bags) or Rigid (hard trays).

Thickness: Typically 100μm – 280μm.

Top Film (Sealing Film):

Material: Composite soft films (e.g., PA/PE, BOPET/PE) or Aluminum Foil.

Thickness: Typically 70μm – 100μm.

Feature: Can be printed with branding/logos.

Q1: What is the main difference between VSP and Vacuum Packing?

Standard vacuum packing uses a flexible bag that wrinkles around the product, often deforming it. VSP uses a rigid tray + a “skin” film that forms a 3D shape without wrinkles, looking much more premium and protecting the food’s shape.

Q2: Can VSP handle liquids/sauces?

Yes. This is a major advantage. Unlike MAP or standard vacuum packs where liquid moves around, VSP locks the liquid in place because the film adheres to the tray surface between food components.

Q3: Does VSP really extend shelf life?

Yes. By removing almost all air and preventing oxidation, VSP offers double the shelf life of MAP (Modified Atmosphere) and up to 4x the shelf life of traditional stretch wrap.

Q4: Can I use paperboard instead of plastic trays?

Yes, our machines are compatible with Paperboard/Laminated Cardboard. This is an excellent option for brands looking to reduce plastic use and improve shelf merchandising.

Q5: What info is needed for a quote?

Email:kbt@kbtfoodpack.com

Tel:+86 15006621717

Add:No. 9999, Mizhou East Road, Zhucheng City, Weifang City, Shandong Province

© 2026 Created with KBT

WhatsApp us