Automatic Operation, Customizable Design, Premium Components.

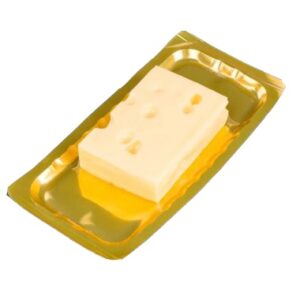

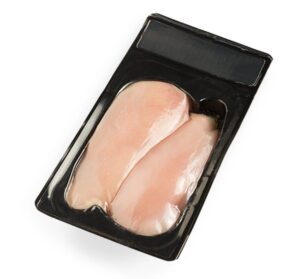

The VSP450A is KANGBEITE’s robust vertical skin packaging solution designed for businesses requiring automatic operation with pre-made trays. Built entirely from food-grade SUS304 stainless steel, this machine ensures compliance with the strictest food hygiene regulations while delivering a stunning “second skin” presentation. It is fully customizable to your specific product dimensions, ensuring a perfect fit for every cycle.

How It Works:

The VSP450A uses a vertical operation method where pre-made trays are loaded into a custom-designed mold. The machine automatically covers the product with heated skin film, applies a powerful vacuum to remove all atmosphere, and seals the film tightly to the tray rim and product surface.

Why Choose the VSP450A?

The VSP450A is a versatile “workhorse” suitable for small to medium-scale food processors.

| Name / Specification | Data / Value |

|---|---|

| Tray Size | Customizable |

| Power Supply | 380V / 50Hz / 3 Phase, or customizable |

| Power | 9 kW |

| Weight | 600 kg |

| Dimensions (L × W × H) | 1500 × 1500 × 1800 mm |

| Trays per Cycle | 2–6 trays |

| Capacity | 2–3 cycles/minute, 600–800 packs/minute |

| Maximum Sealing Film Roll Diameter | 280 mm |

| Vacuum Pump | Busch R5-160 |

| Compressed Air Requirement | 0.6–0.8 MPa |

To achieve the best results with the VSP450A, appropriate materials are required.

Q1: Can I use different tray depths on the same machine?

Yes. The VSP450A features Adjustable Mold Depth. As long as the length and width of the tray remain the same, you can package products of varying heights/depths without needing to buy a new mold.

Q2: How is this machine different from the smaller lab models?

The VSP450A is heavier (500 KG), uses a much more powerful vacuum pump (Busch 160/200), and utilizes Servo Motor drives for precision. It is built for continuous production rather than just lab testing.

Q3: What information is needed for a quote?

Since this machine is totally customizable, we need:

Q4: Is the machine easy to clean?

Yes. The body is made of SUS304 stainless steel and the molds are Aluminum Magnesium alloy. It is designed to be corrosion-proof and meets international food hygiene regulations.

Email:kbt@kbtfoodpack.com

Tel:+86 15006621717

Add:No. 9999, Mizhou East Road, Zhucheng City, Weifang City, Shandong Province

© 2026 Created with KBT

WhatsApp us